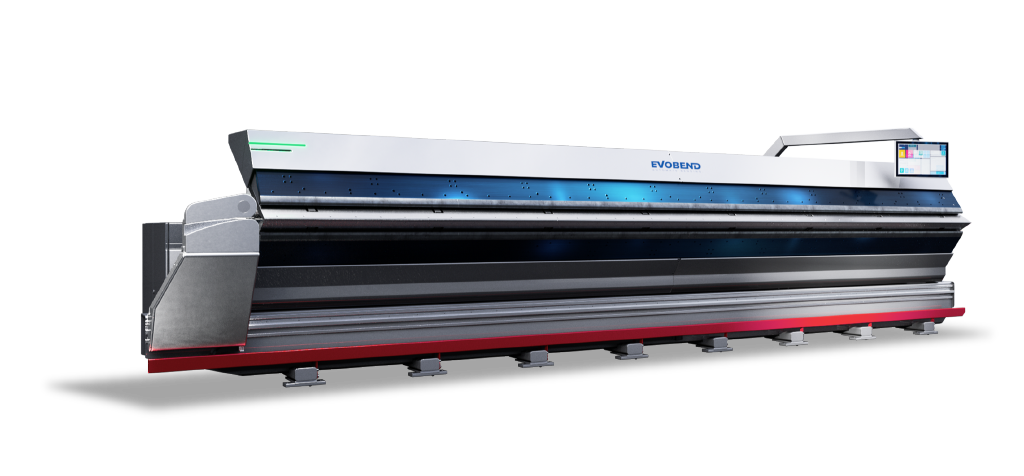

The Evobend’s patented double bending system has been refined in a revolutionary way and enables unmatched bending freedom. Due to the Evobends innovative design, previously impossible angles are now able to be processed. Up to 300° (150° up, 150° down) of bending freedom is unrivaled anywhere else on the market. This increases your flexibility when folding parts and allows for more demanding profiles to be produced at a lower cost.

The virtually scratch-free bending technology of the Evobend provides additional aesthetic value. Until now, bending beams have folded sheets through swivel movements. However, this can permanently damage your sheet metal parts, the “rubbing” of the bending tools on the sheet metal is now a thing of the past! By rolling the bending tools based on your bending curves, minimal marking is left on your work piece.