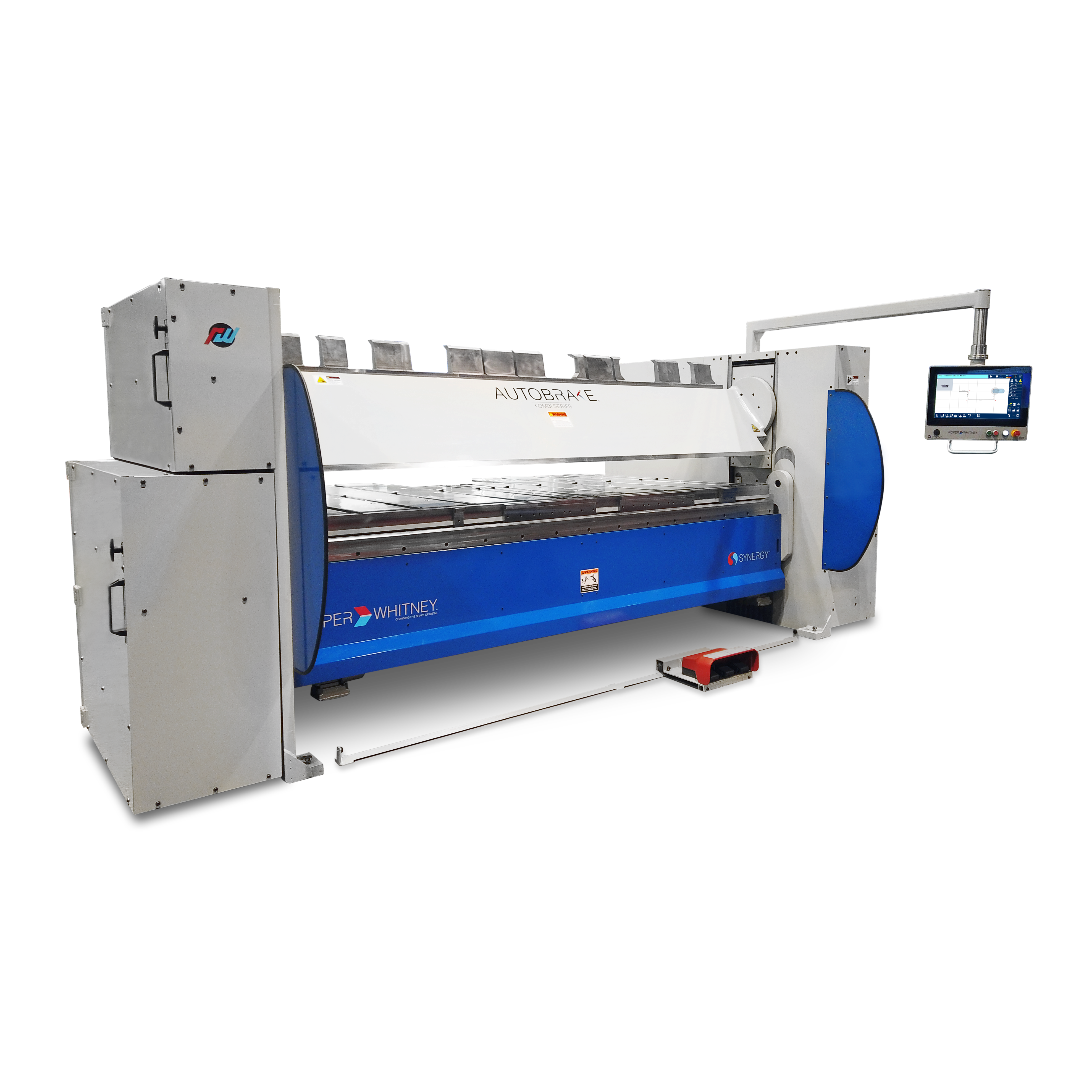

This sheet metal brake is a high speed solution to make a variety of bends while maintaining a high quality level in the end product. The backgauge provides accurate part location through the use of servo drives and is expandable with optional backgauge extensions. The rigid design includes automatic crowning adjustments to ensure accurate bending regardless of raw material stresses. Tooling options are provided to help customize to your specific needs, and can be provided in tool steel or hardened.

The Autobrake design is a plate and weldment steel construction, delivering superior performance and features in a simplified rigid design. End housings are a plate-type construction bringing drive components close together for improved stiffness and performance. Actuating mechanisms are secured in rigid mounts at the outside of the housings, allowing easy maintenance. The bending beam is powered by dual direct drive motors to ensure maximum power and efficiency.

Clamping and hemming capabilities come standard and are already included in the software. Clamping and hemming power is delivered to the clamp jaws by a series of spring washers to provide variable clamping pressures with a shock-absorbing end stop. This provides reliable clamping pressure to create open, tear drop, and closed hems to best suit your needs.

This sheet metal brake comes standard with a rotating Kombi beam. This unique tooling assembly adds to the machines straight and box folding capabilities to produce more complex shapes in less time. It handles a wide range of materials, easily closes hems and withstands the force generated by maximum capacity forming operations. Box tooling is equipped with Roper Whitney’s quick change design allowing for maximum up time and minimized change over time.

Multiple options can be added, at the time of purchase, to maximize the equipment versatility. These options include segmented lower and bend tooling, automated pivot point adjustment, automated up/down backgauge, back gauge extensions for rear operation, and much more. Ask your Roper Whitney sales representative for details.

The Synergy control offers high speed versatility to an end user. It offers multiple methods of programming from simple line-by-line to draw-to-auto program. Its network capabilities allow for multiple options, such as; Konnect, Konstruct, Mobile Konstruct, and overall shop management through linking multiple machines.