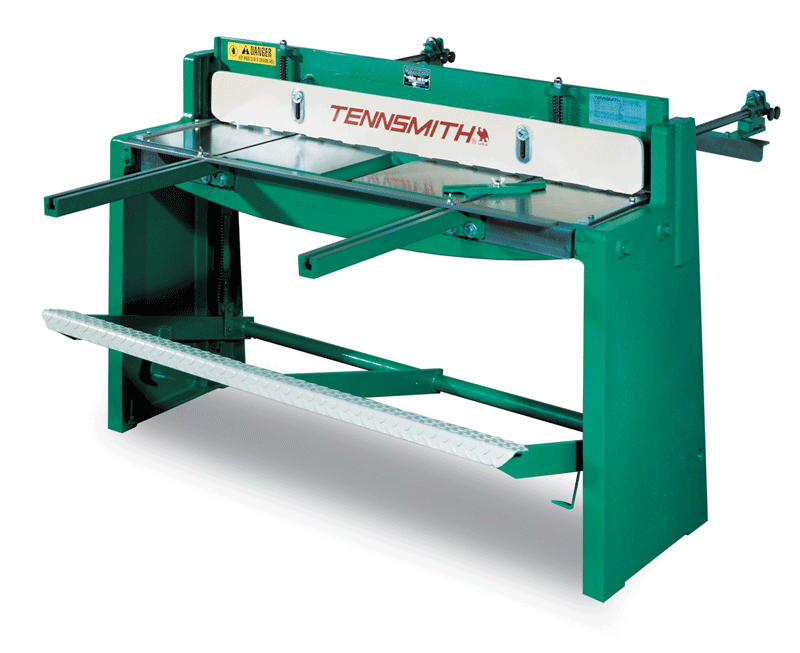

These shears feature tri-action, high-carbon/high chromium (HCHC) steel blades. Both the upper and lower blades have a 2-degree edge relief and the lower blade has an additional 1-degree face relief for maximum material penetration with minimum effort. Tri-action blades help prevent material movement while shearing, prolonging blade life.

Tennsmith shears have the most complete adjustment features of any sheet metal shear on the market. The lower shear blade is bed adjusting and the upper blade is adjustable by means of a truss bar on the cutter head. The spring-activated hold-down feet clamp the work piece securely in place and are easily adjustable to compensate holding pressure for light or heavy gauge material. There is ample clearance between the hold-down feet and shear blades to allow good operator vision for line-of-sight cutting. The standard, double-locking back gauge, which features embossed scales and vernier wheels for fine adjustment, gives highly accurate readings.