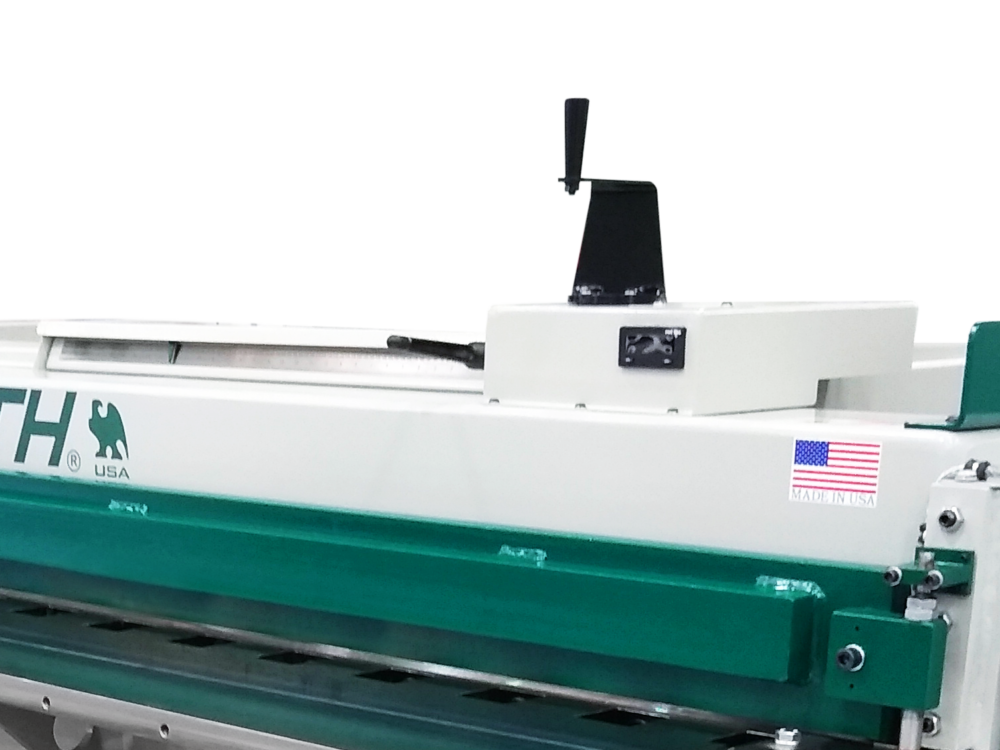

Models LM410, LM610, LM810, LM1010, LM1012, LM1014 and LM1214 incorporate the unique 2x back gauge system. This allows the operator to move the backstop from 0 up to 30 inches (0 to 24 inches for Model LM410) in approximately 2 seconds with only two rotations of the handle. An optional digital readout is available for this system.

The LM Series shears are standard with four edge, high carbon/high chromium (HCHC) top and bottom blades, solid-bar hold-down with non-marring urethane insert, single, continuous and job stroke cycles, motor reverse switch, precision-machined table with hand well, dual inch/metric inlaid bed scales and non-metallic gibs. The LM410 model incorporates all of the popular LM series features into this 52-1/2″ cutting length, 10-gauge mild steel capacity shear. Model LM610 has a rated capacity of 10-gauge mild steel with a maximum cutting length of 60-1/2 inches.

Tennsmith’s LM1010 is standard equipped with a 30-inch powered back gauge system. The ballscrew-driven back gauge provides quick, accurate cuts. The LM1010 is powered by a 12-1/2-hp gear motor attached to a mechanical linkage which provides smooth, quiet operation.

The LM1010 is rated at a maximum of 10-gauge material with a cutting width of 121 inches. To enhance productivity, optional equipment available for the machines include: five or ten-foot squaring arm, front support arms, light beam and protractor attachment. A rear drop sheet support system is available for the LM1010.

Additionally, the LM1010-2x is equipped with the popular 2x manual back gauge option. This allows the operator to move the backstop from 0 to 30 inches in approximately two seconds with only two rotations of the handle. An optional digital readout is available for this system.

Air-Operated Sheet Support System Available as F (front) or R (rear)

Shown is F option

The LM Series shears are now available in an optional “Performance Package” configuration which includes a 5′ squaring arm, a pair of front support arms, and an air operated sheet support is available in two styles:

- System R drops the supported material to the rear of the machine.

- System F returns the supported material to the front of the machine via a front return chute.

If you are adding a shears product to your quote and are interested in the optional Performance Package, follow link below to select your system to add to quote.

The Synergy Control system is a state-of-the-art, user-friendly control interface designed to enhance precision and efficiency in metal cutting. It eliminates the need for manual adjustments and significantly boosting cutting accuracy. The system includes an extensive material library, allowing users to store and easily access various material types, colors, and thicknesses. Additionally, its program library facilitates the storage and retrieval of cutting programs, making repetitive tasks and complex job sequences more manageable. With features like Konstruct integration for streamlined job handling, the Synergy Control system is an essential tool for modern metalworking, offering unparalleled control and customization in metal shearing operations.

With the combination of the optional digital readout for 2x back gauge system, the operator adds both speed and great accuracy to the job. The optional digital display shows measurements in 0.001” increments. Longer travel ranges are available by request.

The optional five-foot squaring arm is a precision gauge, which can be mounted left or right and has inlaid inch/metric scaling and adjustable guide block. Also available in ten and twelve-foot lengths. A toggle on the block lets sheet stock slide underneath, then pivots to the stop position.

The optional powered back gauge system features a twin ball screw design which provides accuracy and repeatability. The standard travel range is 30-inches, longer travels are available. The back gauge is powered by a 3/4–hp gear motor and operated by a powered control system. Models LM1010 and LM1210 are standard with this system.

- Five-foot squaring arm

- 10-foot squaring arm

- Front support arms

- T-slotted table (supports arms with inlaid inch/metric scales)

- Material cart (MSE1016 and LM1014)

- Stroke counter

- Protractor for angled cuts

- Go-To ball screw driven back gauge

- High speed motors for increased cutting cycles

- Air-operated sheet support system (front or rear return)

- Performance Packages