|

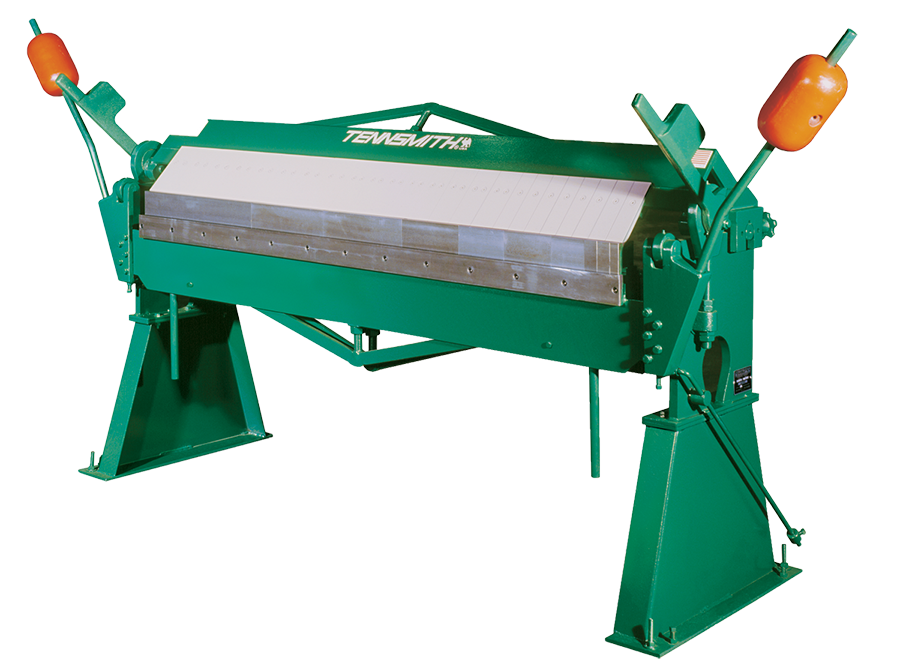

HBT48-12 |

HBT72-16 |

EBT60-16 |

| Capacity, Mild Steel |

12 Gauge

2.7 mm |

16 Gauge

1.6 mm |

16 Gauge

1.6 mm |

| Capacity, with Bending Support Angle Removed, Mild Steel |

16 Gauge

1.6 mm |

20 Gauge

1.0 mm |

|

| Bending Length |

48 in.

1220 mm |

72 in.

1828.8 mm |

60-1/4 in.

1537 mm |

| Maximum Lift Of Beam |

1-1/2 in.

38.1 mm |

1-1/2 in.

38.1 mm |

4 in.

102 mm |

| Front To Rear Beam Adjustment |

1/2 in.

13 mm |

1/2 in.

13 mm |

1 in.

25 mm |

| Maximum Depth Of Box |

4 in.

101.6 mm |

4 in.

101.6 mm |

4-1/8 in.

105 mm |

| Minimum Reverse Bend |

5/8 in.

16 mm |

5/8 in.

16 mm |

5/8 in.

16 mm |

| Minimum Flange In Capacity Material |

1 in.

25 mm |

1 in.

25 mm |

|

| Top Segment Tooling Widths |

2, 3, 4 in.

50.8, 76.2, 101.6 mm |

2, 3, 4 in.

50.8, 76.2, 101.6 mm |

|

| Lower Segment Tooling Widths |

1, 1-1/2, 4, 6, 8, 12, 20 in.

25, 38, 102, 152, 203, 305, 508 mm |

1, 1-1/2, 4, 6, 8, 12, 20 in.

25, 38, 102, 152, 203, 305, 508 mm |

1, 1-1/2, 4, 6, 8, 12, 20 in.

25, 38, 102, 152, 203, 305, 508 mm |

| Bending Beam Tooling Segments |

1, 1-1/2, 6, 8, 12, 20 in.

25, 38, 152, 203, 305, 508 mm |

1, 1-1/2, 4, 6, 8, 12, 20 in.

25, 38, 102, 152, 203, 305, 508 mm |

|

| Maximum Transverse Bend (through tooling centers) |

2 in.

50.8 mm |

2 in.

50.8 mm |

2-1/4 in.

57 mm |

| Maximum Transverse Bend (at either end of machine) |

3 in.

76.2 mm |

3 in.

76.2 mm |

|

| Dimensions (counterweights in place) |

72 x 36 x 53 in.

1829 x 915 x 1346 mm |

89-1/2 x 36 x 53 in.

2273 x 915 x 1346 mm |

72 x 45-1/2 x 31-1/2 in.

1829 x 1156 x 800 mm |

| Shipping Weight |

1750 lbs.

795 kg |

2200 lbs.

1000 kg |

1150 lbs.

521.6 kg |